Publications

Work in progress

arXiv

Domain Structure and Interface Control of Mechanical Stiffness in Sustainable Cellulose Bio-nanocomposites

H. Jin, W. Goldberg, Z. Wang, H. Li, Y. Huang, M. Foston, G.M. Genin†

arXiv 2024 | arXiv: 2412.13210

In revision

In situ mechanical characterization of functional and architected materials

H. Jin, M. Chen, M. Kagias, M. Abi Ghanem, B. Zhang, H.D. Espinosa†

In revision 2025

Engineered protein-cellulose composite hydrogels with superior mechanical performance for bioadhesion

J. Jeon, Z. Wang, M. Li, M. Senanayake, S.V. Pingali, H. Jin, K.Z. Lee, S.V. Subramani, L. Belaygorod, B. Arif, G.M. Genin, M. Foston, M.A. Zayed, F. Zhang†

In revision 2025

In preparation

Generic nanostructural mechanics and multiscale modeling of programmable protein-based hydrogels

H. Jin*, Y. Huang*, J. Jeon, M. Mudiyanselage, F. Zhang, M. Foston, G.M. Genin†

In preparation 2025

Vibrational mechanobiology: the role of the extracellular matrix

H. Jin, T. Anttonen, A. Mekkanakkil, A. Phan, O. Tchaicheeyan, R. Zaera Polo, B. Mortimer, A. Lesman, G.M. Genin†

In preparation 2025

2025

Characterization and Inverse Design of Stochastic Mechanical Metamaterials Using Neural Operators

H. Jin, B. Zhang, Q. Cao, E. Zhang, A. Bora, S. Krishnaswamya, G. E. Karniadakis, H. D. Espinosa†

Advanced Materials 2025, 2420063

Machine learning (ML) is emerging as a transformative tool for the design of mechanical metamaterials, offering properties that far surpass those achievable through lab-based trial-and-error methods. However, a major challenge in current inverse design strategies is their reliance on extensive computational and/or experimental datasets, which becomes particularly problematic for designing micro-scale stochastic architected materials that exhibit nonlinear mechanical behaviors. Here, a comprehensive end-to-end scientific ML framework, leveraging deep neural operators (including DeepONet and its variants) is introduced, to directly learn the relationship between the complete microstructure and mechanical response of architected metamaterials from sparse but high-quality in situ experimental data. Various neural operators and standard neural networks are systematically compared to identify the model that offers better interpretability and accuracy. The approach facilitates the efficient inverse design of structures tailored to specific nonlinear mechanical behaviors. Results obtained from stochastic spinodal microstructures, printed using two-photon lithography, reveal that the prediction error for mechanical responses is within a range of 5 - 10%. This work underscores that by employing neural operators with advanced nano- and micro-mechanical experiments, the design of complex micro-architected materials with desired properties becomes feasible, even in scenarios constrained by data scarcity. This work marks a significant advancement in the field of materials-by-design, potentially heralding a new era in the discovery and development of next-generation metamaterials with unparalleled mechanical characteristics derived directly from experimental insights.

Tuning sustainable nanocomposite interphase behavior through surface modification of cellulose nanocrystals

Z. Wang, H. Li, H. Jin, M. Senanayake, S.V. Pingali, W. Goldberg, D. Kobayashi, G.M. Genin, M. Foston†

Polymer Composites 2025

DOI: 10.1002/pc.70050

Sustainable alternatives to petroleum-based plastics are needed urgently, but biodegradable materials from renewable sources often suffer from inadequate mechanical properties. Here, we demonstrate a bio-inspired strategy to enhance soy protein isolate (SPI) nanocomposites through surface modification of cellulose nanocrystal (CNC) reinforcing filler particles with a polydopamine (polyDOPA) coating via dopamine polymerization under alkaline conditions. This modification creates multifunctional interfaces at filler surfaces that enhance nanocomposite mechanical properties likely by simultaneously altering filler dispersion and filler–matrix interactions. PolyDOPA-modified CNCs increase the tensile strength and elastic modulus of SPI films (plasticized with 50% glycerol) by more than threefold compared to unreinforced controls. Transmission electron microscopy, spectroscopic techniques, and thermal analysis reveal that polyDOPA coatings influenced nanocomposite structure across multiple length scales, tripling the effective diameter of the CNC inclusions, reducing the tendency of CNC nanocrystals to aggregate, and increasing the glass transition temperature. The increase in glass transition temperature suggests reduced SPI molecular mobility, which, along with micromechanical modeling, indicates the potential for improved interfacial interactions. Results reveal how polyDOPA-modified CNCs influence the interphase behavior and filler dispersion of SPI-glycerol nanocomposites, providing a pathway to further improve their performance for various applications, including packaging, membranes, and coatings.

2024

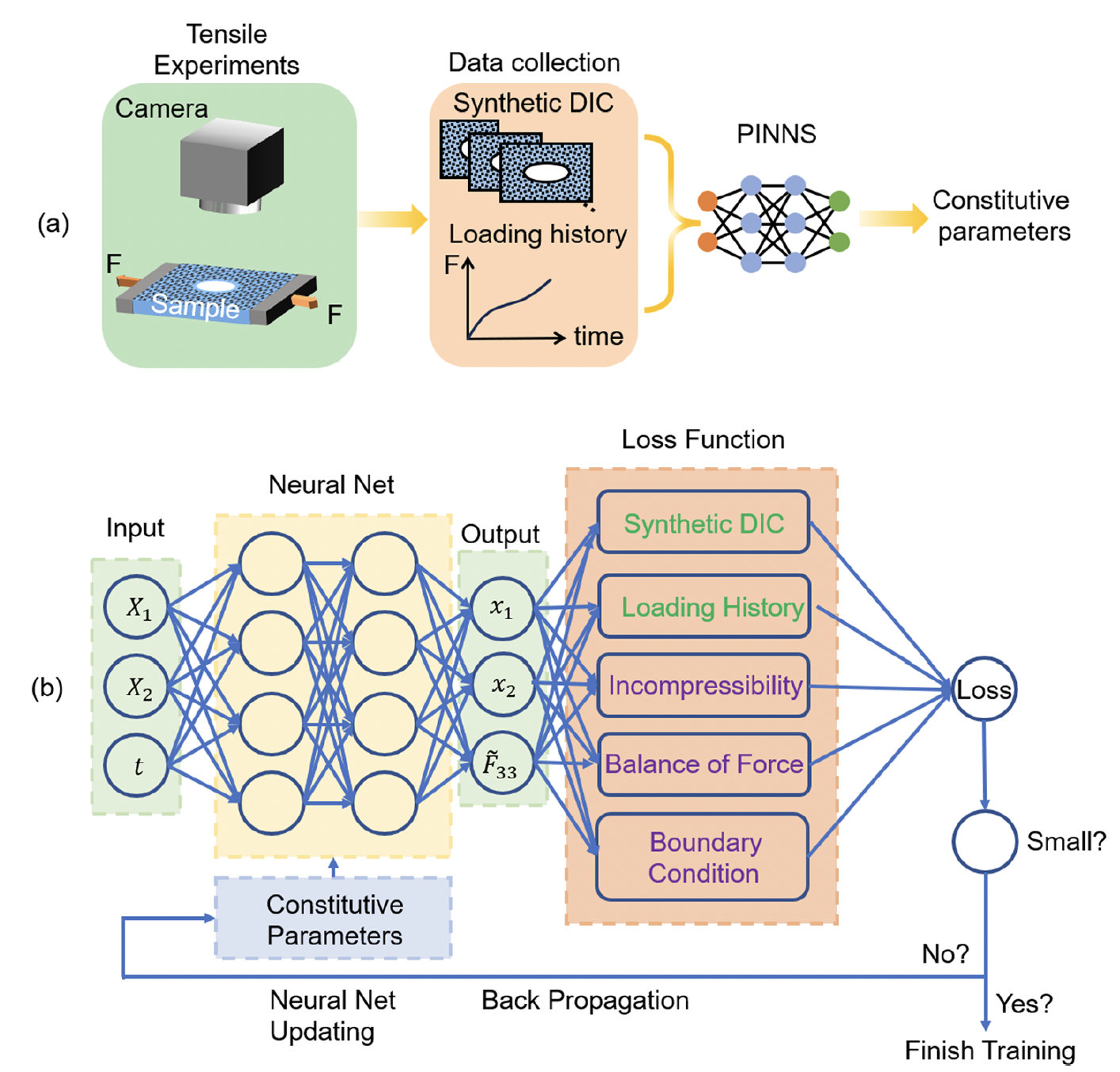

Identifying constitutive parameters for complex hyperelastic materials using physics-informed neural networks

S. Song, H. Jin†

Soft Matter 2024, 20(30), 5915-5926

DOI: 10.1039/D4SM00001C

Identifying constitutive parameters in engineering and biological materials, particularly those with intricate geometries and mechanical behaviors, remains a longstanding challenge. The recent advent of physics-informed neural networks (PINNs) offers promising solutions, but current frameworks are often limited to basic constitutive laws and encounter practical constraints when combined with experimental data. In this paper, we introduce a robust PINN-based framework designed to identify material parameters for soft materials, specifically those exhibiting complex constitutive behaviors, under large deformation in plane stress conditions. Distinctively, our model emphasizes training PINNs with multi-modal synthetic experimental datasets consisting of full-field deformation and loading history, ensuring algorithm robustness even with noisy data. Our results reveal that the PINNs framework can accurately identify constitutive parameters of the incompressible Arruda–Boyce model for samples with intricate geometries, maintaining an error below 5%, even with an experimental noise level of 5%. We believe our framework provides a robust modulus identification approach for complex solids, especially for those with geometrical and constitutive complexity.

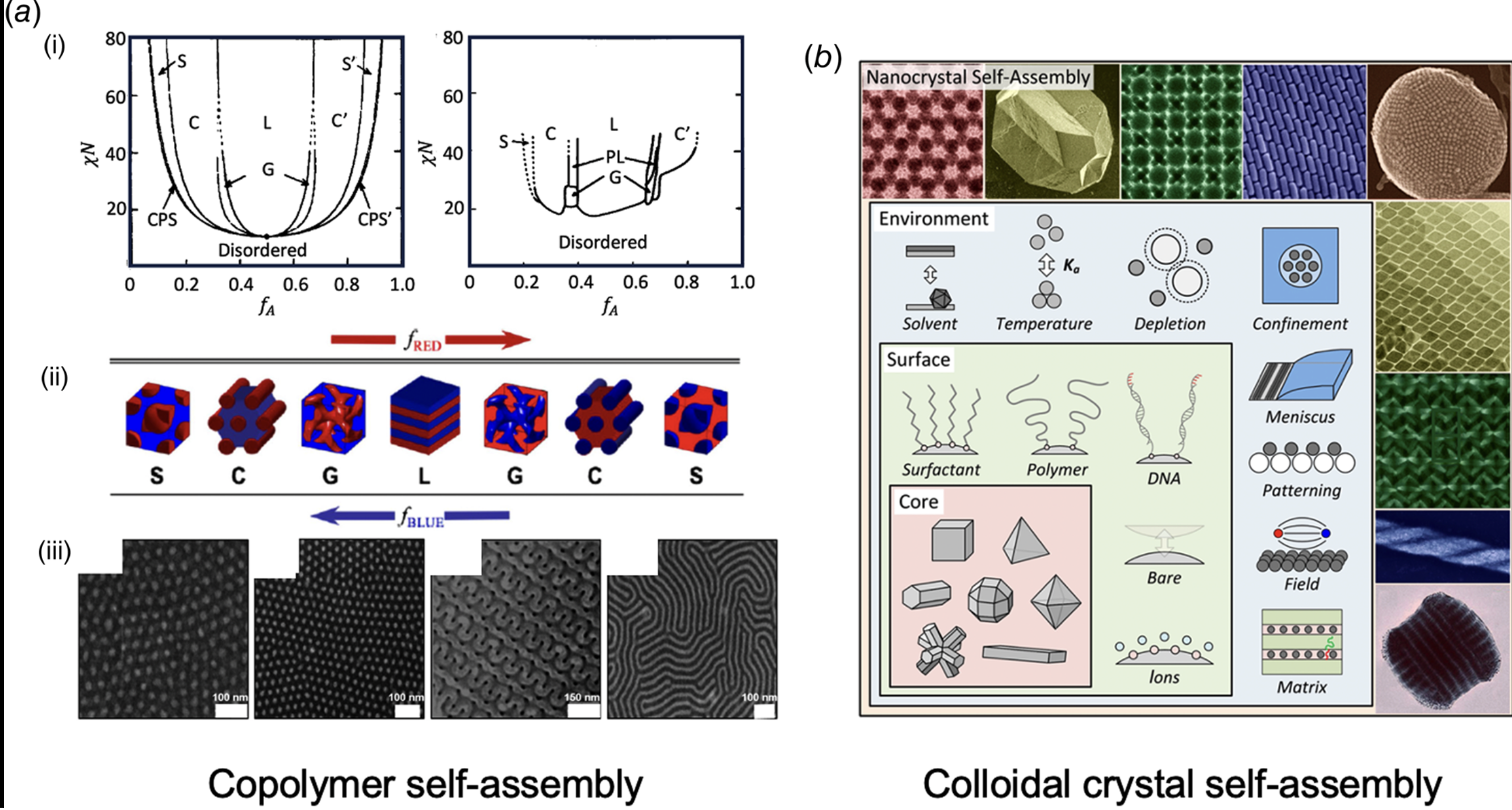

Mechanical metamaterials fabricated from self-assembly: A perspective

H. Jin†, H. D. Espinosa†

Journal of Applied Mechanics 2024, 91 (4), 040801.

DOI: 10.1115/1.4064144

Mechanical metamaterials, whose unique mechanical properties stem from their structural design rather than material constituents, are gaining popularity in engineering applications. In particular, recent advances in self-assembly techniques offer the potential to fabricate load-bearing mechanical metamaterials with unparalleled feature size control and scalability compared to those produced by additive manufacturing (AM). Yet, the field is still in its early stages. In this perspective, we first provide an overview of the state-of-the-art self-assembly techniques, with a focus on the copolymer and colloid crystal self-assembly processes. We then discuss current challenges and future opportunities in this research area, focusing on novel fabrication approaches, the need for high-throughput characterization methods, and the integration of Machine Learning (ML) and lab automation for inverse design. Given recent progress in all these areas, we foresee mechanical metamaterials fabricated from self-assembly techniques impacting a variety of applications relying on lightweight, strong, and tough materials.

2023

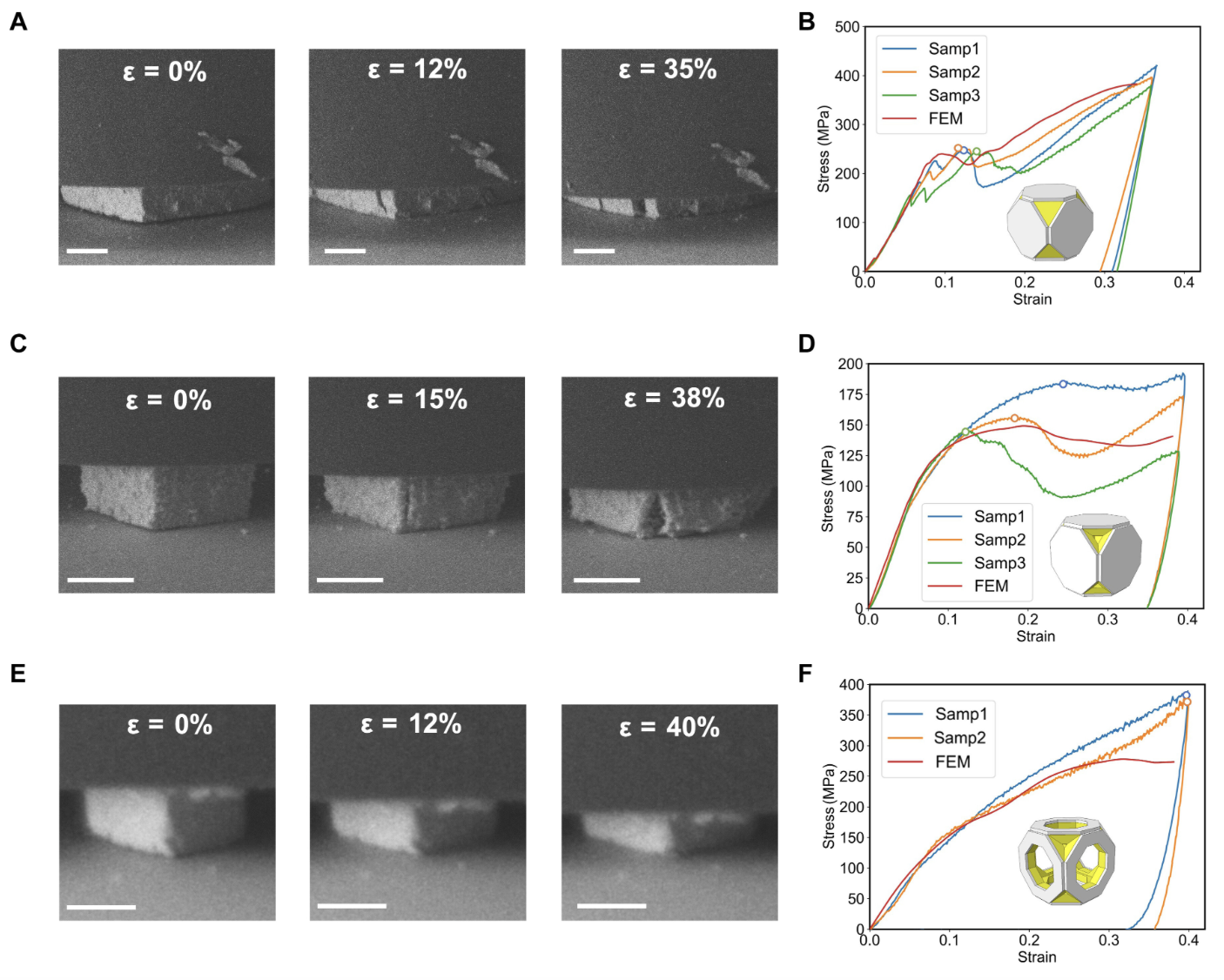

Ultrastrong colloidal crystal metamaterials engineered with DNA

Y. Li*, H. Jin*, W. Zhou, Z. Wang, Z. Lin, C.A. Mirkin†, H.D. Espinosa†

Science Advances 2023, 9 (39), eadj8103

Lattice-based constructs, often made by additive manufacturing, are attractive for many applications. Typically, such constructs are made from microscale or larger elements; however, smaller nanoscale components can lead to more unusual properties, including greater strength, lighter weight, and unprecedented resiliencies. Here, solid and hollow nanoparticles (nanoframes and nanocages; frame size: ~15 nanometers) were assembled into colloidal crystals using DNA, and their mechanical strengths were studied. Nanosolid, nanocage, and nanoframe lattices with identical crystal symmetries exhibit markedly different specific stiffnesses and strengths. Unexpectedly, the nanoframe lattice is approximately six times stronger than the nanosolid lattice. Nanomechanical experiments, electron microscopy, and finite element analysis show that this property results from the buckling, densification, and size-dependent strain hardening of nanoframe lattices. Last, these unusual open architectures show that lattices with structural elements as small as 15 nanometers can retain a high degree of strength, and as such, they represent target components for making and exploring a variety of miniaturized devices.

Recent advances and applications of machine learning in experimental solid mechanics: A review

H. Jin, E. Zhang, H.D. Espinosa†

Applied Mechanics Reviews 2023, 75(6): 061001

DOI: 10.1115/1.4062966

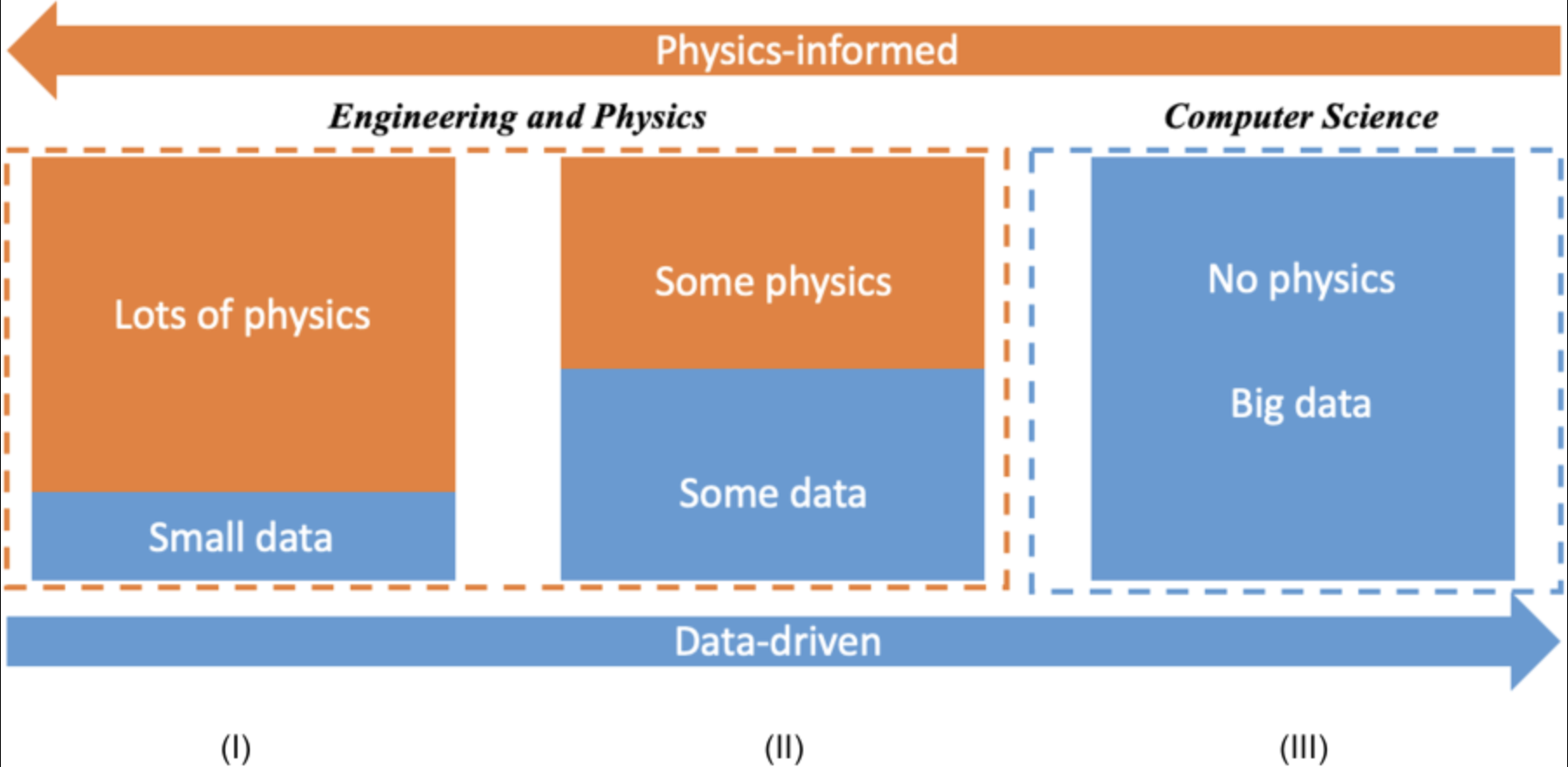

For many decades, experimental solid mechanics has played a crucial role in characterizing and understanding the mechanical properties of natural and novel artificial materials. Recent advances in machine learning (ML) provide new opportunities for the field, including experimental design, data analysis, uncertainty quantification, and inverse problems. As the number of papers published in recent years in this emerging field is growing exponentially, it is timely to conduct a comprehensive and up-to-date review of recent ML applications in experimental solid mechanics. Here, we first provide an overview of common ML algorithms and terminologies that are pertinent to this review, with emphasis placed on physics-informed and physics-based ML methods. Then, we provide thorough coverage of recent ML applications in traditional and emerging areas of experimental mechanics, including fracture mechanics, biomechanics, nano- and micromechanics, architected materials, and two-dimensional materials. Finally, we highlight some current challenges of applying ML to multimodality and multifidelity experimental datasets, quantifying the uncertainty of ML predictions, and proposing several future research directions. This review aims to provide valuable insights into the use of ML methods and a variety of examples for researchers in solid mechanics to integrate into their experiments.

2022

Dynamic fracture of a bicontinuously nanostructured copolymer: A deep-learning analysis of big-data-generating experiment

H. Jin, T. Jiao, R.J. Clifton, K.-S. Kim†

Journal of the Mechanics and Physics of Solids 2022, 164, 104898

DOI: 10.1016/j.jmps.2022.104898

Here, we report measurements of detailed dynamic cohesive properties (DCPs) beyond the dynamic fracture toughness of a bicontinuously nanostructured copolymer, polyurea, under an extreme loading rate, from deep-learning analyzes of a dynamic big-data-generating experiment. We first describe a new Dynamic Line-Image Shearing Interferometer (DL-ISI), which uses a streak camera to record optical fringes of displacement-gradient vs time profile along a line on sample’s rear surface. This system enables us to detect crack initiation and growth processes in plate-impact experiments. Then, we present a convolutional neural network (CNN) based deep-learning framework, trained by extensive finite-element simulations, that inversely determines the accurate DCPs from the DL-ISI fringe images. For the measurements, plate-impact experiments were performed on a set of samples with a mid-plane crack. A Conditional Generative Adversarial Networks (cGAN) was employed first to reconstruct missing DL-ISI fringes with recorded partial DL-ISI fringes. Then, the CNN and a correlation method were applied to the fully reconstructed fringes to get the dynamic fracture toughness, cohesive strength, and maximum cohesive separation, within 0.4%, 2.7%, and 2.2% differences, respectively. For the first time, the DCPs of polyurea have been successfully obtained by the DL-ISI with the pre-trained CNN and correlation analyzes of cGAN-reconstructed data sets. The dynamic cohesive strength is found to be nearly three times higher than the dynamic-failure-initiation strength. The high dynamic fracture toughness is found to stem from both high dynamic cohesive strength and high ductility of the dynamic cohesive separation. These experimental results fill a gap in the current understanding of nanostructured copolymer’s cooperative-failure strength under extreme local loading conditions near the crack tip. This experiment demonstrates the advantages of a big-data-generating experiment to extract unprecedented details of nanostructured material’s dynamic fracture characteristics with deep-learning algorithms.

2021

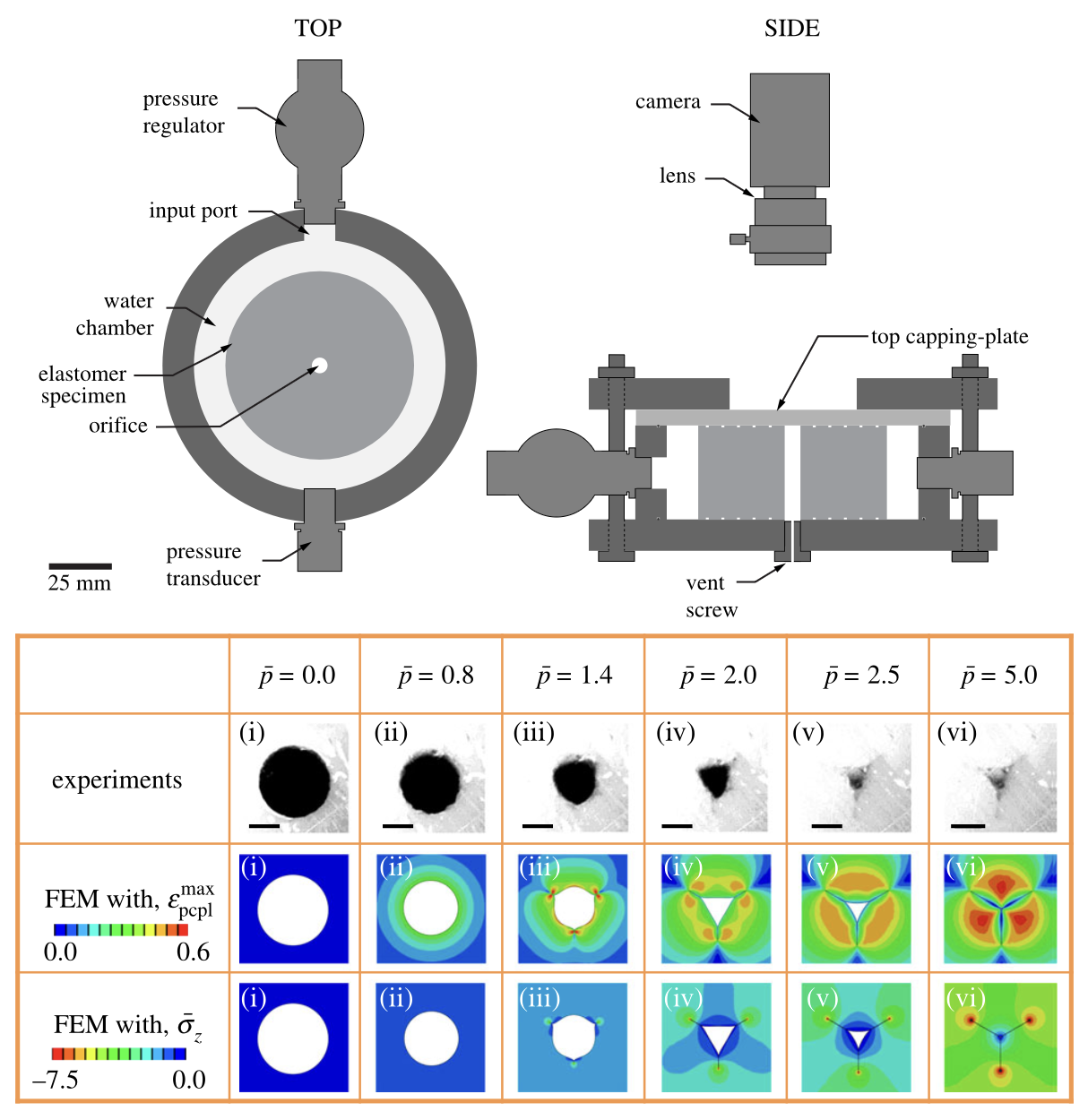

Ruga mechanics of soft-orifice closure under external pressure

H. Jin, A.K. Landauer, K.-S. Kim†

Proceedings of the Royal Society A 2021, 477 (2249), 20210238

Here, we report the closure resistance of a soft-material bilayer orifice increases against external pressure, along with ruga-phase evolution, in contrast to the conventional predictions of the matrix-free cylindrical-shell buckling pressure. Experiments demonstrate that the generic soft-material orifice creases in a threefold symmetry at a limit-load pressure of p/μ ≈ 1.20, where μ is the shear modulus. Once the creasing initiates, the triple crease wings gradually grow as the pressure increases until the orifice completely closes at p/μ ≈ 3.0. By contrast, a stiff-surface bilayer orifice initially wrinkles with a multifold symmetry mode and subsequently develops ruga-phase evolution, progressively reducing the orifice cross-sectional area as pressure increases. The buckling-initiation mode is determined by the layer’s thickness and stiffness, and the pressure by two types of the layer’s instability modes—the surface-layer-wrinkling mode for a compliant and the ring-buckling mode for a stiff layer. The ring-buckling mode tends to set the twofold symmetry for the entire post-buckling closure process, while the high-frequency surface-layer-wrinkling mode evolves with successive symmetry breaking to a final closure configuration of two- or threefold symmetry. Finally, we found that the threefold symmetry mode for the entire closure process provides the orifice’s strongest closure resistance, and human saphenous veins remarkably follow this threefold symmetry ruga evolution pathway.

Understanding the nanoscale deformation mechanisms of polyurea from in situ AFM tensile experiments

H. Jin†, C. Machnicki, J. Hegarty, R.J. Clifton, K.-S. Kim

Conference Proceedings of the Society for Experimental Mechanics Series 2021

DOI: 10.1007/978-3-030-86737-9_6

Here, we report in situ AFM tapping-phase study of polyurea’s nano and mesoscale phase transitions within the submicron-size field of view. To this end, we designed and assembled a novel in situ AFM loading device that keeps a reference point stationery within the observation window. Using this device, we acquired sequential AFM-tapping-mode phase images of polyurea’s nanophase evolution during relaxation under various fixed tensile strains up to 200%. We found that initial hard nano-domains fragment upon rapid loading and the fragmented hard phases go through various nano and mesoscale phase transitions. These fragmented pieces are recombined to form coarsened bicontinuous clusters during the relaxation process. The AFM in situ testing enables us to better understand dynamic-bond characteristics of segmented block copolymers. Interplay between the dynamic-bond characteristics of supramolecular interactions and the hard/soft-phase load/deformation sharing characteristics is believed to predict the self-healing and dynamic toughening mechanisms of polyurea.

2020

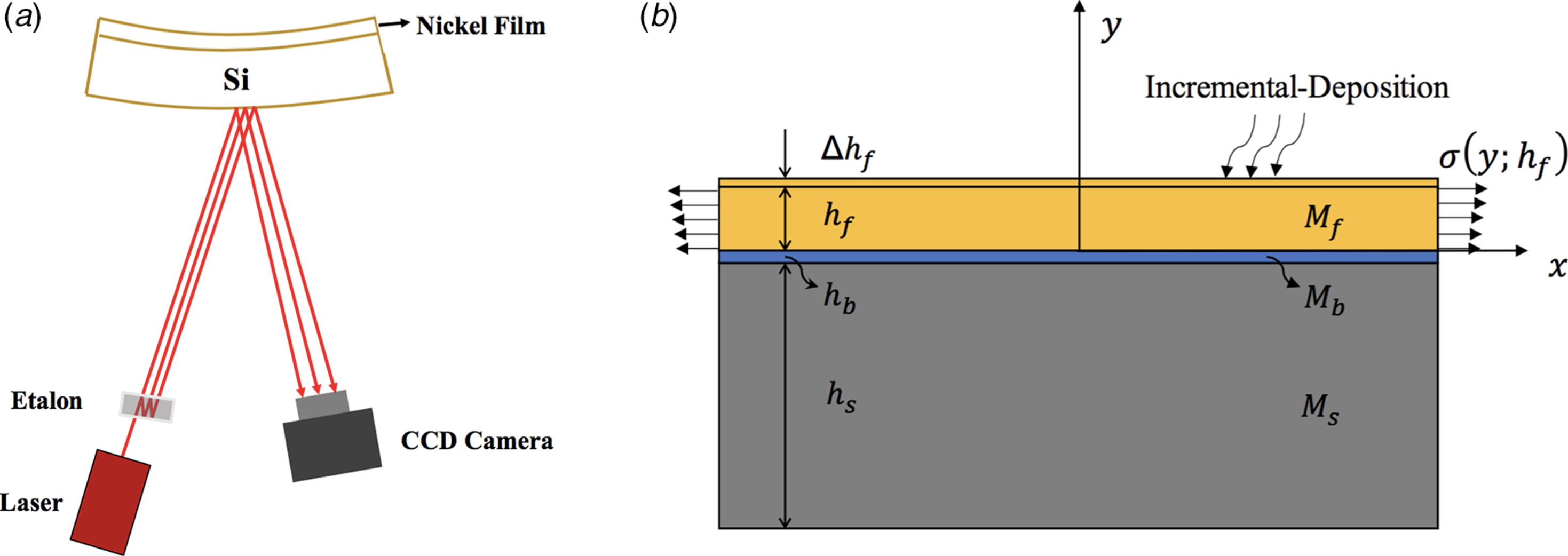

Determination of stresses in incrementally deposited films from wafer-curvature measurements

Z. Rao, H. Jin, A. Engwall, E. Chason, K.-S. Kim†

Journal of Applied Mechanics 2020, 87 (10), 101006.

DOI: 10.1115/1.4047572

We report closed-form formulas to calculate the incremental-deposition stress, the elastic relaxation stress, and the residual stress in a finite-thickness film from a wafer-curvature measurement. The calculation shows how the incremental deposition of a new stressed layer to the film affects the amount of the film/wafer curvature and the stress state of the previously deposited layers. The formulas allow the incremental-deposition stress and the elastic relaxation to be correctly calculated from the slope of the measured curvature versus thickness for arbitrary thicknesses and biaxial moduli of the film and the substrate. Subtraction of the cumulative elastic relaxation from the incremental-deposition stress history results in the residual stress left in the film after the whole deposition process. The validities of the formulas are confirmed by curvature measurements of electrodeposited Ni films on substrates with different thicknesses.

Earlier Publications

Grain size gradient and length scale effect on mechanical behaviors of surface nanocrystalline metals

H. Jin, J. Zhou†, Y. Chen

Materials Science and Engineering: A 2018, A 725, 1-7.

DOI: 10.1016/j.msea.2018.03.001

Distribution effects of secondary twin lamellae on the global and local behavior of hierarchically nanotwinned metals

H. Jin, J. Zhou†

Journal of Materials Science 2017, 52 (8), 4647-4657.

DOI: 10.1007/s10853-016-0708-8

For a complete list of publications, please visit my Google Scholar profile.

NanoBioMech Lab

NanoBioMech Lab