Toward Resilient and Sustainable Nano-Bio-Structured Materials

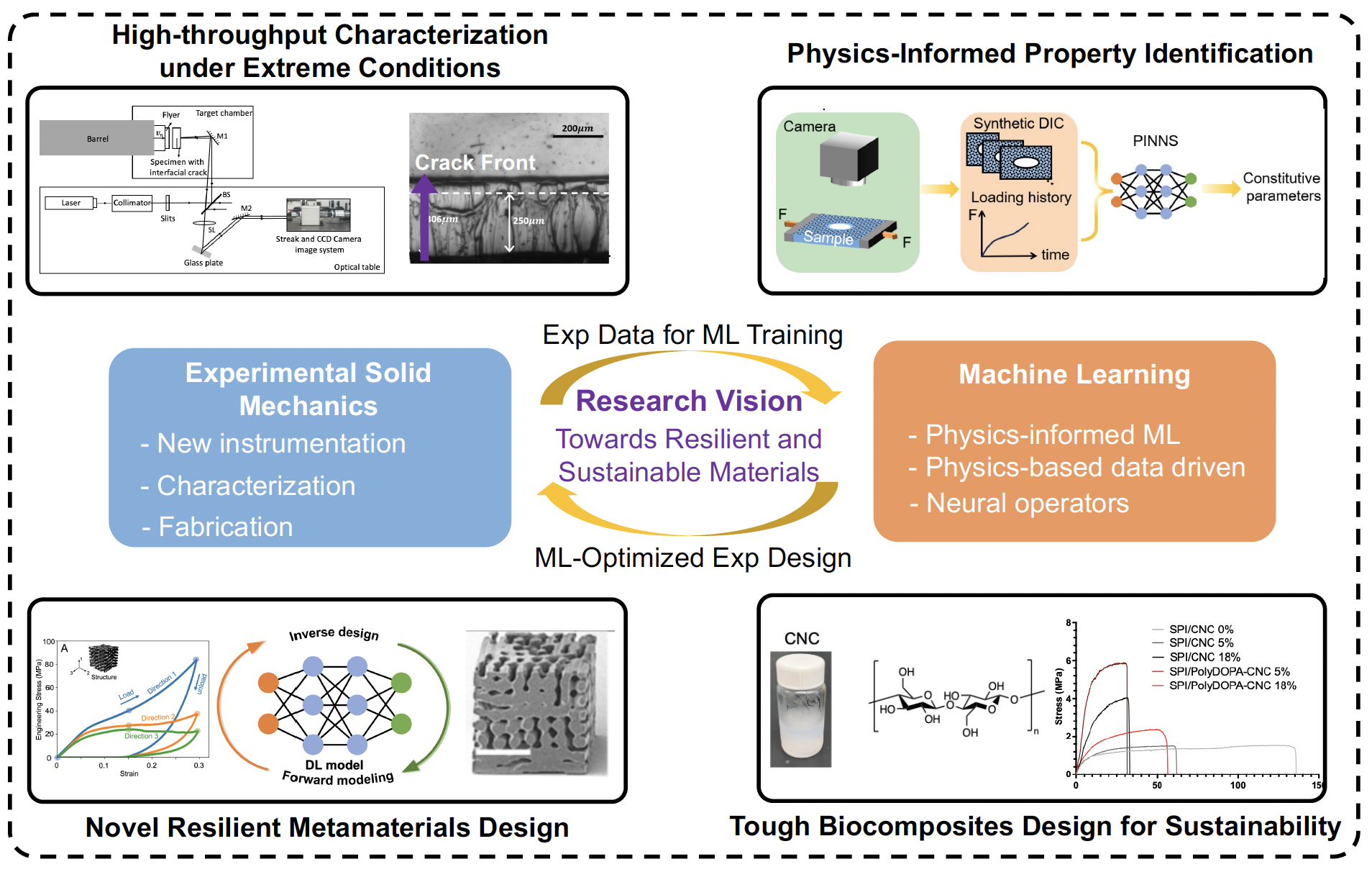

We integrate multiscale mechanics, scientific AI/ML, and sustainable fabrication to create next-generation nano-bio-materials for healthcare and engineering applications.

Developing next-generation materials for human health demands an interdisciplinary approach that bridges solid mechanics, materials science, machine learning, and bioengineering. Our group’s long-term research vision is to pioneer the design of nano-bio-materials that are mechanically robust, biologically compatible, and environmentally sustainable, while being precisely tunable to meet individualized clinical needs.

Topic 1. Biomanufacturing and Multiscale Mechanobiological Characterization

We design and fabricate nano-bio-structured materials that emulate the structural and mechanical complexity of living tissues. By integrating biomanufacturing with mechanobiological characterization, we aim to uncover how micro-architectural and mechanical cues regulate cell behavior, matrix remodeling, and tissue morphogenesis.

Sustainable Biofabrication: We integrate natural collagen and biopolymer-based inks to create functional cell scaffolds that combine high mechanical performance with a minimal environmental footprint. These biofabrication approaches enable precise control over microstructure, composition, and interfacial properties.

Mechanobiological Characterization: We employ multiscale in-situ testing and advanced imaging to quantify how mechanical properties and biological responses evolve across scales. Techniques such as nanoindentation, AFM, and micro-tensile testing are combined with fluorescent live-cell imaging to capture dynamic cell–matrix interactions, stiffness heterogeneity, and viscoelastic responses in engineered tissues and ECM-inspired scaffolds.

Mechanics Modeling: We develop predictive mechanics models (continuum and discrete-based) that couple microstructural deformation with cellular mechanotransduction, enabling us to understand how architecture, damage, and energy dissipation in bio-structured materials influence cell mechanics, signaling, and tissue-level function.

Related work:

H. Jin, W. Goldberg, Z. Wang, H. Li, Y. Huang, M. Foston, G.M. Genin. “Domain Structure and Interface Control of Mechanical Stiffness in Sustainable Cellulose Bio-nanocomposites.” arXiv, 2024. arXiv: 2412.13210

H. Jin*, Y. Huang*, J. Jeon, M. Mudiyanselage, F. Zhang, M. Foston, G.M. Genin. “Generic nanostructural mechanics and multiscale modeling of programmable protein-based hydrogels.” In preparation, 2025.

Y. Li*, H. Jin*, W. Zhou, Z. Wang, Z. Lin, C.A. Mirkin, H.D. Espinosa. “Ultrastrong colloidal crystal metamaterials engineered with DNA.” Science Advances, 2023. DOI: 10.1126/sciadv.adj8103

H. Jin, A.K. Landauer, K.-S. Kim. “Ruga mechanics of soft-orifice closure under external pressure.” Proceedings of the Royal Society A, 2021. DOI: 10.1098/rspa.2021.0238

Topic 2. AI-Driven Rapid Design of Novel Nano-Bio-Structures for Personalized Healthcare

We envision a future where AI-driven design transforms materials discovery from trial-and-error to precision engineering. By embedding physics-informed machine learning, we accelerate the creation of nano-bio-materials with precisely targeted mechanical and biological responses, enabling personalized solutions for healthcare and sustainable engineering.

Neural Operators for Data-Driven Mechanics Modeling: We develop neural operator frameworks (e.g., DeepONet) that learn the nonlinear behavior of heterogeneous materials directly from sparse experimental and numerical data. We have demonstrated these methods in designing stochastic spinodal microstructures and are working on collagen-inspired and kirigami metamaterials with programmable stiffness and toughness.

Physics-Informed Neural Networks (PINNs) for Mechanistic Learning: To ensure interpretability and physical fidelity, we embed mechanical governing equations, boundary conditions, and conservation laws into neural networks. We apply them to capture multiscale hyperelastic and viscoelastic responses of biological tissues and hydrogels, linking molecular assembly to macroscopic function.

Translational AI for Biomedical Devices and Mechanobiology: Integrating these AI surrogates with inverse and generative design algorithms (e.g., genetic algorithms, reinforcement learning), we explore vast design spaces for biomedical and mechanobiological applications. This includes rapid prototyping of bio-inspired scaffolds and cardiac tissue models, where optimized architectures balance mechanical performance, biocompatibility, and cellular mechanotransduction. Our long-term vision is to establish a closed-loop AI-assisted platform for intelligent design, fabrication, and mechanical characterization of functional bio-materials.

Related work:

H. Jin, B. Zhang, Q. Cao, E. Zhang, A. Bora, S. Krishnaswamya, G.E. Karniadakis, H.D. Espinosa†. “Characterization and Inverse Design of Stochastic Mechanical Metamaterials Using Neural Operators.” Advanced Materials, 2025. DOI: 10.1002/adma.202420063

S. Song, H. Jin†. “Identifying constitutive parameters for complex hyperelastic materials using physics-informed neural networks.” Soft Matter, 2024. DOI: 10.1039/D4SM00001C

H. Jin, E. Zhang, H.D. Espinosa†. “Recent advances and applications of machine learning in experimental solid mechanics: A review.” Applied Mechanics Reviews, 2023. DOI: 10.1115/1.4062966

H. Jin, T. Jiao, R.J. Clifton, K.-S. Kim†. “Dynamic fracture of a bicontinuously nanostructured copolymer: A deep-learning analysis of big-data-generating experiment.” Journal of the Mechanics and Physics of Solids, 2022. DOI: 10.1016/j.jmps.2022.104898

NanoBioMech Lab

NanoBioMech Lab